As discussed and explored in the exhibition Deep-seated. The Secret Art of Upholstery at the Grassi Museum für Angewandte Kunst, Leipzig, the cushioning that is so central, so defining, in contemporary seating, and in contemporary interiors, has a long (hi)story, a long (hi)story related to technical and cultural changes, a long (hi)story which has both been informed by and has contributed to changes in society.

And a long (hi)story for the greater part primarily told in natural materials, be that plants, wool, horsehair et al, before becoming one of synthetic plastics.

With Pouls Universitatea de Artă și Design, UAD, Cluj-Napoca, Romania, student, possibly alumni, Daniel Melente proposes a future hi(story) of upholstery told, once again, in a natural material: wood.

Whereby, we're fairly certain Pouls isn't the first proposal for wooden upholstery we've seen, not that in this moment we could actually name the others we in our ageing brains and cloudy memories believe we have at some point seen. But whether or not it is the first is largely irrelevant, for Pouls is a very interesting and instructive proposal.

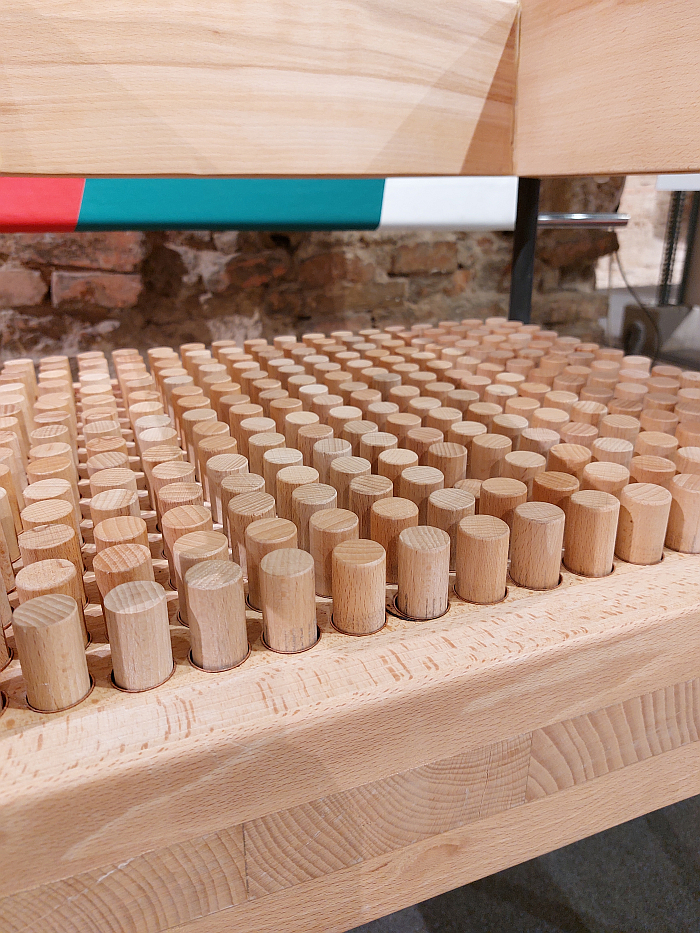

Essentially a pegboard, a concept that, arguably, has existed since the days of the earliest contemporary humans, and which is found across genres and contexts, the defining aspect of Pouls is that the pegs are retractable, they sink under pressure into the board, and rise again once that pressure is removed. Yes, we did push a few, despite the prominent 'Do not touch' sign, sorry, but we had to understand how they moved, how firm they were, how much resistance they offered, how rapidly or slowly they moved, etc, etc ...didn't however sit on it, sadly, for that is always one of the key tests of any and every chair. But on pushing the pegs we got the impression that sufficient resistance was at play to ensure a comfortable sitting experience.

A sitting experience, presumably, in certain regards, related to that of sitting on the bed of nails as popularised by the stereotypical European gaze image of the fakir, and which, again presumably, we really can't say without having sat on it, is an experience with a similar disparity between the perception of how it will be and how it actually is: is presumably a lot more comfortable that you would or could imagine. Although arguably will take a bit of getting used to. Which isn't an issue

What is an issue, or certainly potentially an issue, is that while achievable in a one off, or in small scale craft production, sprung wooden peg upholstery as proposed by Daniel will, we strongly suspect, invariably prove impractical on an industrial scale.

Or will via traditional wood production methods. But in 3D printed wood?

Viewing Pouls in the vastness of the former Kiscell church we kept coming back to the consideration, strong belief, pun intended, that such a retractable pegboard is the sort of thing 3D printing technology is inherently suitable for. Or could be, there is invariably (a lot of) development work to be completed first, not least in terms of the durability and accuracy of the 'springs', the resistance system; but, in our ageing brains, through printing the pegs and board and mechanism in one object you save a lot of production steps and employee hours. Yes there are issues with repairing any potential damage, but resolve them, and the many other issues, and you have a new upholstery concept that, as with all developments in upholstering before it, is related to technical and cultural changes and which is informed by and contributes to changes in society.

As does, could, will, the more general adoption of 3D printing in furniture design, production and distribution, something neatly alluded to by the project Ambla by UAD Cluj-Napoca alumni Tania Man that stands next to Pouls in Design Without Borders; a project that offers a take on the 3D printable connector as the basis for extended furniture systems. A concept that has been around for a while, exists in innumerable propositions and concepts, and where you must ask yourself, certainly we regularly ask ourselves, when will a major furniture manufacturer or retailer pluck up the courage to seize the initiative and realise an actual system that actual people people can actually use in their actual lives?

Yes, such does, would, involve re-imaging, re-structuring, how furniture is produced and sold, and how profit is made from furniture production and selling, but is such a re-imagining, re-structuring so bad? Or perhaps long overdue?

3D printed connectors that for us make sense for a myriad reasons, not least that through empowering the end user to continually create and recreate the furniture objects they need, and that at the moment of an Enzo Mari's "concrete need"1, you enable responsive furniture systems that allow for an individual interior for each of our individual realities; responsive furniture systems which approach answers to a Rudolf Horn's questions of "how despite mass production the consumer can realise an individual [domestic] environment" and "how the cultured personality can creatively contribute to the design of their immediate surroundings"2, while actively reducing the resource footprint of furniture production and provision, allow for a more sustainable and responsible production and provision of furniture. All the more so if that production and provision of such connectors, and the other elements required, is locally based, locally accessible, locally relevant (and open source).

It's next level modularity, a carrying forth of the ideals that underscore modularity into a new technology and material future.

And 3D printed connectors that also make sense for us because furniture designers shouldn't create furniture but frameworks and systems for the realisation of furniture.

Ambla is and was an engaging and instructive argument for both those positions.

Just as Pouls is and was an engaging and instructive argument for wooden upholstery. 3D printed or conventionally carpented.

A chair which aside from its upholstering proposition, one which in its use of a natural material helps us all reduce our reliance on synthetic plastics, which can only be positive, presents itself with a chunkiness of seat that is, inarguably, related to the need for space for the pegs to retract into, an enforced chunkiness of seat which Daniel has very pleasing voluntarily transposed to the armrests and backrests which don't require it, a correspondence between the two parts that greatly contributes to visual joy of Pouls; and, even more pleasingly, Daniel has connected the chunky seat and the chunky arm/backrests via (relatively) thin steel tubing which enables what, inarguably, could very easily have been an unwieldy massive, solid, object more akin to the 16th century than the 21st to posses a lightness, agility and ease. A mixing of (relatively) thin steel tubing and chunky wood that reminds more of a readymade, or more accurately a 1980s bricolage than the considerately crafted and constructed chair Pouls is, without seeking to be a 1980s bricolage, very much wanting to be a considerately crafted and constructed chair. And a mixing of (relatively) thin steel tubing and chunky wood that bequeaths Pouls an improbability.

As does the retractable wooden peg upholstery.

An improbability that was just one of many things we enjoyed about Pouls, and just one of the many reasons that long after having left Design Without Borders, we're still engaging with Pouls. And probably will be for a while to come.

More information on Daniel Melente and Pouls can be found at... we no know. We can find nothing online. Sorry!! Should that change, we will update. Or research yourself, the UAD Cluj-Napoca website is one possible starting place.

And more details on Design Without Borders, including information on the 2024 edition, can be found at https://design-without-borders.eu

1"the real need for a manufactured object correspond[s] to the moment of its production. This is the concrete need": see Hans Ulrich Obrist, The Conversation Series 15: Enzo Mari, Verlag der Buchhandlung Walther König, Cologne, 2008, page 38

2Rudolf Horn, Industriell gefertigte Montagemöbel, Deutsche Architektur, XVII Jahrgang, March 1968